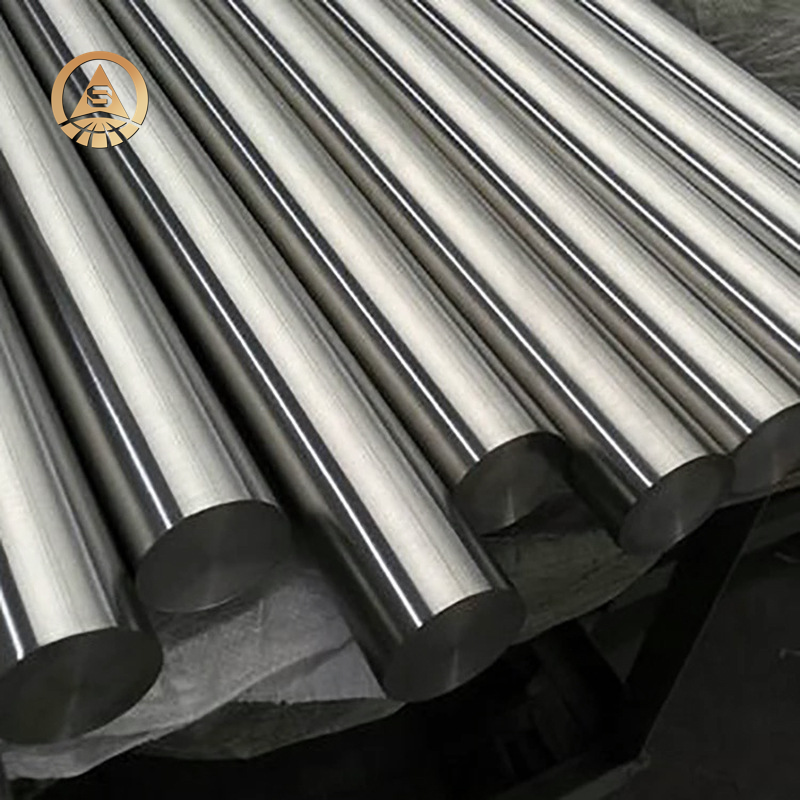

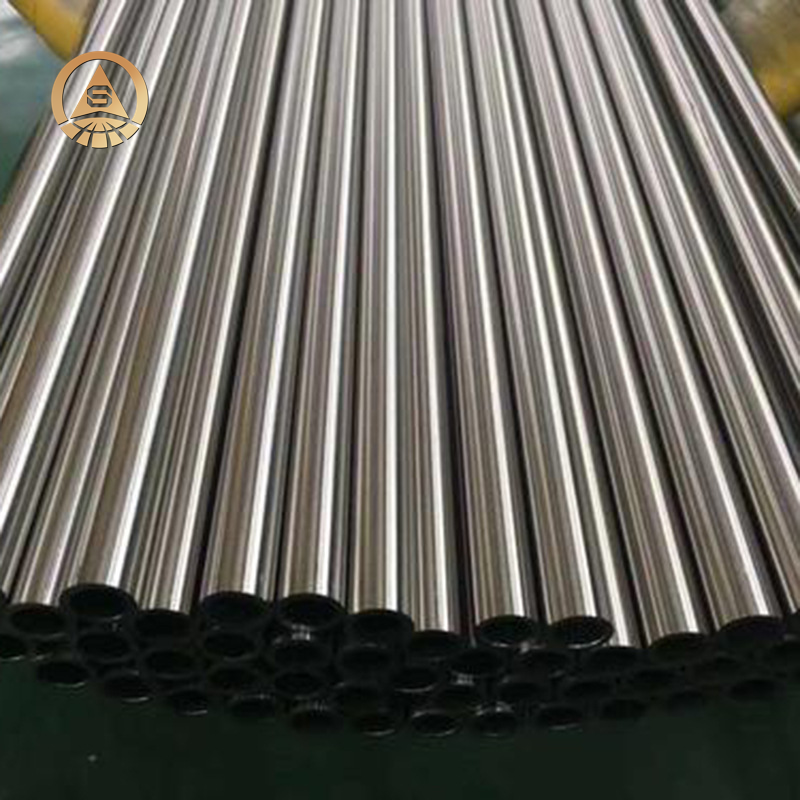

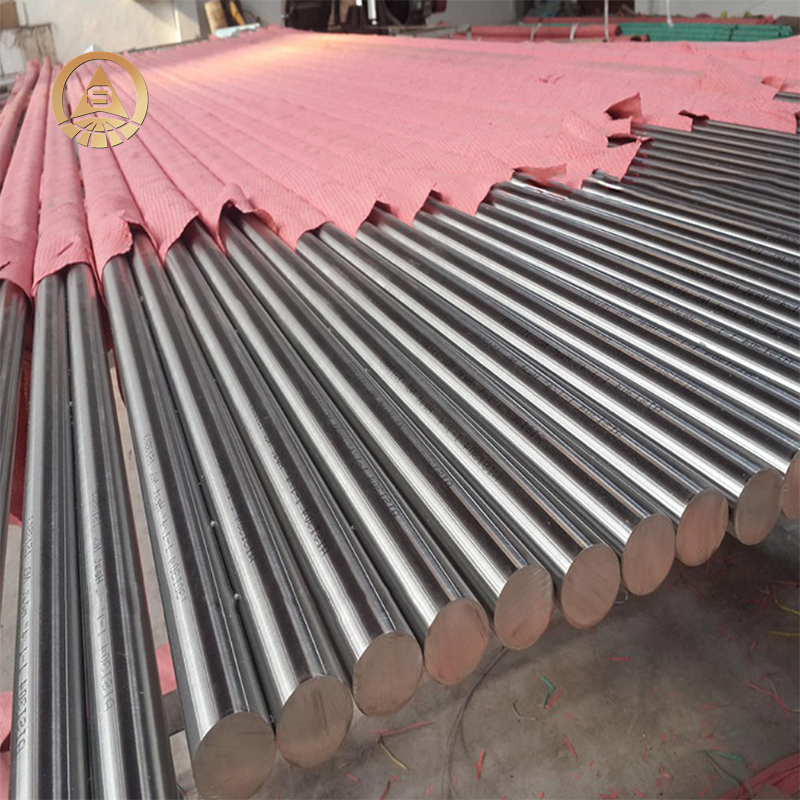

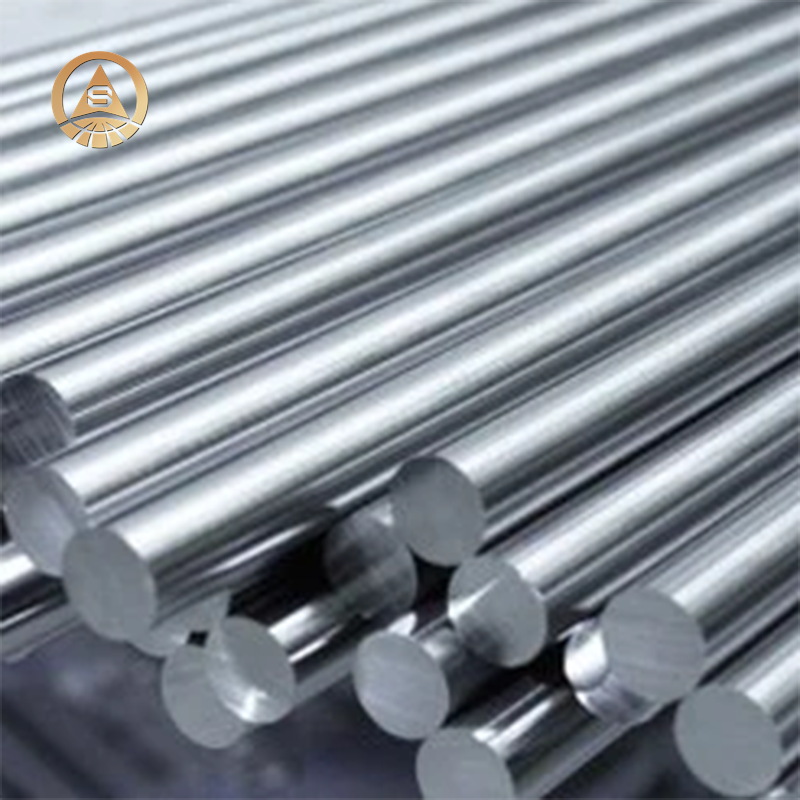

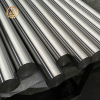

Product Description Inconel 625 Bar

The strength of Inconel 625 bar derives from the solid solution strengthening effect of molybdenum and niobium contained in the nickel-chromium alloy. These elements also make the alloy highly resistant to corrosion. While the alloy is designed for strength in high-temperature environments, it also has a high degree of resistance to general corrosion as well as resistance to a wide range of oxidizing and non-oxidizing environments. The chromium and molybdenum content make the alloy highly resistant to corrosion spots caused by chloride ions, and the high nickel content enhances the alloy’s resistance to chloride stress corrosion cracking. The material is highly formable and easier to weld than many nickel-based alloys. Even under welded conditions, the alloy still has the ability to resist intergranular corrosion, in addition to corrosion and oxidation resistance.

Product Parameters

| Product Name | Inconel 625 Bar | |

| Outer Diameter | Round Bar | 4mm-500mm |

| Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

| Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

| Flat Steel | 1/2 “to 10”, Thickness: 2mm-150mm, Can provide customized | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, NO.4, BA, etc. | |

| Certificate | ISO, SGS, BV | |

| Production Technology | Hot Rolling, Cold Rolling | |

Chemical Composition

| C

|

Mg | Al | Si | P | S | Ti | Cr | Fe | Co | Ni | Mo | Cb (Nb Ta) |

| 0.1 max | 0.5 max | 0.4 max | 0.5 max | 0.015 max | 0.015 max | 0.4 max | 20.00 – 23.00 | 5.0 max | 1.0 max | 58.0 min | 8.0 – 10.0 | 3.15 – 4.15 |

Mechanical Properties

| Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

| 120 | 60 | 30 |

Alloy steel bar size table

| Size (mm) | Size (inch) | Size (mm) | Size (inch) |

| 25mm | 1″ | 63mm | 2-1/2″ |

| 30mm | 1-3/16″ | 65mm | 2-5/9″ |

| 32mm | 1-1/4″ | 70mm | 2-3/4″ |

| 35mm | 1-3/8″ | 75mm | 3″ |

| 40mm | 1-4/7″ | 80mm | 3-1/8″ |

| 45mm | 1-7/9″ | 90mm | 3-1/2″ |

| 50mm | 2″ | 100mm | 4″ |

| 55mm | 2-3/16″ | 150mm | 6″ |

Commonly used materials include: 600, 601, 625, 718, X-750etc.